Box clever

The COP26 summit has focused new attention on the contribution that supply and distribution chains, especially in ecommerce, make to greenhouse gas (GHG) emissions and other environmental ills. Many leading companies have publicly committed to change but, as consultants McKinsey note: “In many instances net zero commitments are running ahead of companies’ own plans to meet them”.

Clearly, it will take years, and much innovation and investment in material production, product design and distribution technology, to deliver net-zero supply of the products that consumers want and need. But one step that ecommerce businesses could take, economically, effectively, and right now, is to stop delivering what consumers neither want nor need – excess packaging.

If businesses are serious about aligning their policies to COP26 objectives, then simple, obvious steps to reducing waste should be taken now.

The cardboard box is a wonderful invention, but the commonplace experience of receiving small items in grossly oversized packaging often filled with non-recyclable polyethylene or polystyrene void fill, has moved from amusing, through annoying, to downright scandalous. This is a  wasteful act that undermines efforts to attain a net-zero future.

wasteful act that undermines efforts to attain a net-zero future.

As a material, cardboard packaging may be far more environmentally acceptable than its petro-chemical based alternatives, but it is still a valuable resource that should be used as thoughtfully and sparingly as possible. Making and recycling paper and cardboard is an energy-intensive process using significant amounts of hot water, so keeping the amount of cardboard we use to an absolute minimum is an important step on the journey to achieving a net-zero supply chain.

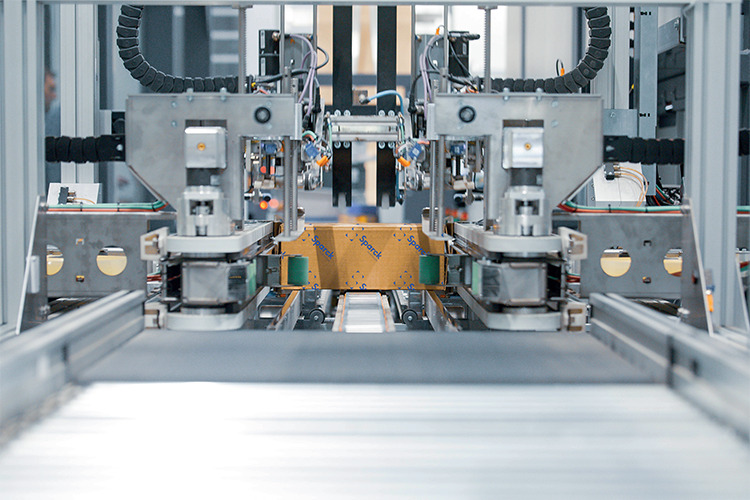

The ecommerce sector has an opportunity, indeed, a duty, to use available technology to make right-sized packaging for each individual ecommerce order. Sparck Technologies (formerly Quadient) offers CVP Automated Packaging Solutions that create ‘right-size’ boxes in seconds by scanning and measuring the goods – single or multi-item orders – cutting and erecting the box, sealing, weighing, and labelling. Interestingly, multiple corrugate feeders are becoming more popular with ecommerce businesses as different widths of cardboard can be selected automatically by the machine to minimize off-cuts – and branded board is also an option.

By minimizing corrugate use, cardboard consumption reduces by 30 percent on average and void fill is virtually eliminated, significantly reducing packaging material costs. And as businesses are well aware, cardboard is under significant upward price pressure.

Furthermore, using smaller boxes means a greater density of product per truck or van load. A reduction in volume for a given quantity of goods of up to 50 percent potentially reduces the number of trucks required on trunk routes, and the empty running caused by ‘last mile’ vehicles having to return to depot to reload in mid-shift – both of which can significantly reduce transport GHG emissions and costs, as well as other environmental harms, from noise pollution to congestion.

CVP packaging solutions also conserve other scarce resources. Labor shortages are driving up staffing costs in the logistics industry, but right-size packaging can help reduce the requirement for drivers and staff within the warehouse – a CVP machine can typically replace between eight and 20 manual packing stations. Up to 500 shipments an hour can be produced by the CVP Impack machine, and 1100 packages an hour on the CVP Everest. They can also save on another resource that is becoming increasingly expensive – warehouse space.

Many net zero strategies are widely believed to reduce consumer choice, or impair productivity and profit, or require large upfront investment for slow and uncertain gain, or require wholesale change to products, processes and business models throughout the supply chain. However, CVP Automated Packaging Solutions offer a compelling economic case by improving productivity while reducing transport, labor and material costs, along with an immediate and verifiable improvement in the supply chain’s carbon footprint.

Importantly, far from adversely impacting consumers, more efficient packaging will be immediately noticed and valued by the half of consumers who rate over-size packaging as one of the most annoying features of ecommerce, and the 77 percent who believe that the packaging a brand uses reflects its environmental values.

Right-sized packaging offers a net zero contribution that is environmentally effective, commercially attractive, and available right now.

Jo Bradley

Jo Bradley

Jo Bradley is Business Development Manager at Sparck Technologies (formerly Packaging by Quadient) a global leader in the design and fabrication of advanced, fit-to-size automated packaging systems for high-volume ecommerce applications – award-winning sustainable packaging solutions that eliminate excessive packaging. It aims to make every parcel its clients send out a brand ambassador for their business. Based in Drachten, The Netherlands, Sparck Technologies supplies some of the world’s largest retail and industrial brands, supporting their ecommerce channels in multiple geographies with market-leading engineering know-how that combines innovation, reliability and unbeatable performance.

https://sparcktechnologies.com